Oil-Immersed Transformer Problems & Solutions – Expert Prevention Guide

Discover top oil-immersed transformer failures (leaks, overheating, insulation issues) and proven prevention methods. Boost reliability with 2024 maintenance tips!

1. Insulation System Failures (45% of Cases)

Key Problems:

- Transformer oil degradation (acid value >0.1mg KOH/g)

- Moisture contamination (>30ppm)

- Solid insulation carbonization

Prevention:

✅ Oil testing every 6 months (DGA for H₂, C₂H₂ gases)

✅ Use vacuum oil purifiers (keep moisture <15ppm)

✅ Select high-stability oil (KI≥55) for replacements

2. Oil Leakage Issues (25% of Cases)

Common Leak Points:

- Gasket seals (hardens in 3-5 years)

- Valve flanges

- Radiator weld seams

Solutions:

🔧 Install fluororubber gaskets (-40℃~200℃ resistant)

🔧 Use torque wrenches (bolt pressure ≤35N·m)

🔧 UV fluorescent dye testing (detects 0.1mm cracks)

3. Overheating Risks (15% of Cases)

| Cause | Critical Temp | Solution |

|---|---|---|

| Overloading | >105℃ | Install fiber-optic sensors |

| Cooling system clog | ΔT oil >25K | Monthly radiator cleaning |

| Tap changer contact wear | Local >130℃ | Use vacuum OLTC |

4. Electrical Faults (10% of Cases)

Critical Issues:

- Winding short circuits (partial discharge >10pC)

- Bushing flashover (insufficient creepage)

- Core ground faults (>100mA current)

Prevention:

⚠️ Annual FRA winding tests

⚠️ Silicone composite bushings (anti-pollution)

⚠️ Core ground current monitors

5. Emergency Failures (5% of Cases)

- False gas relay trips → Install oil flow relays

- Pressure relief valve sprays → Use dual-piston valves (<70kPa)

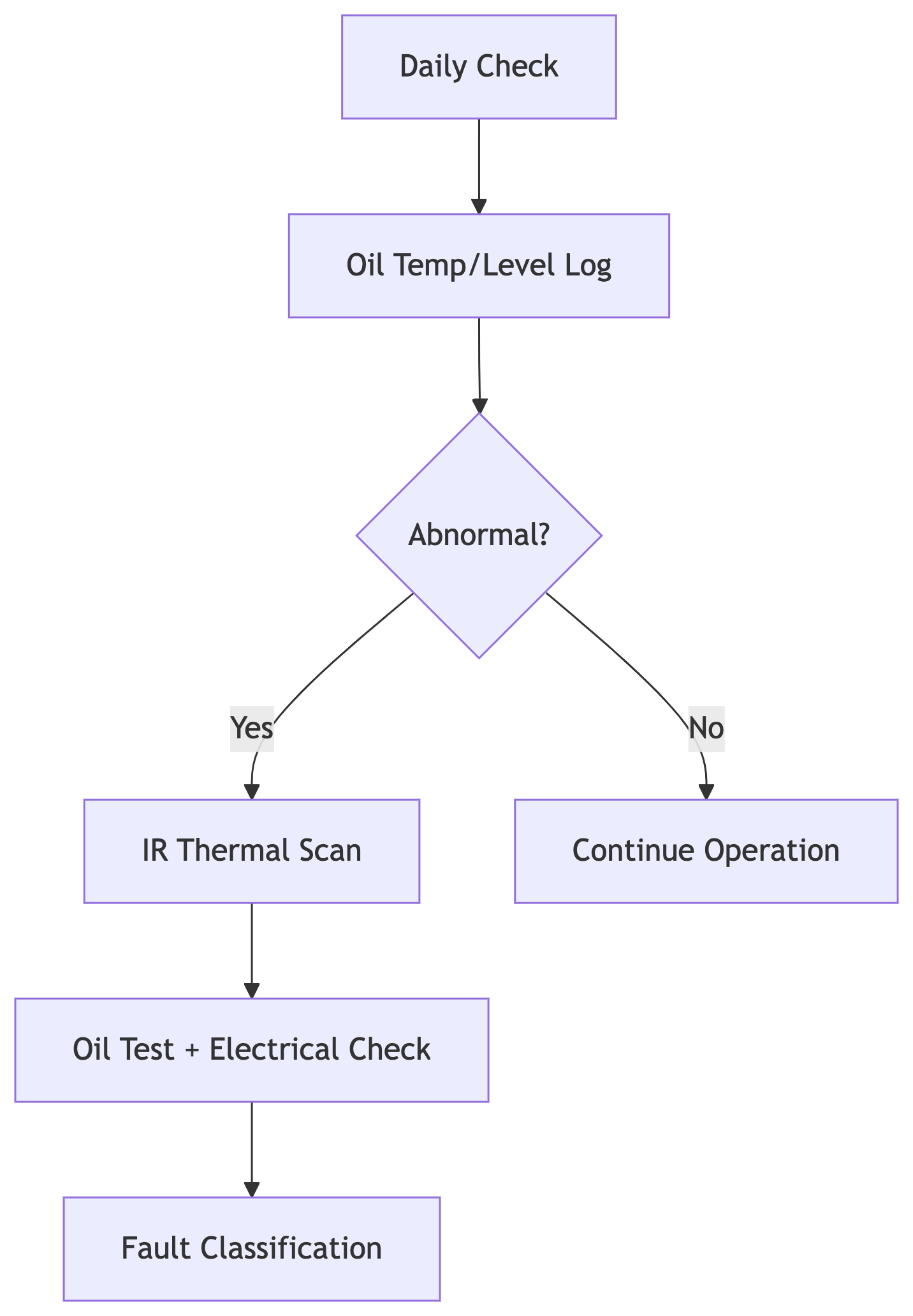

Maintenance Gold Standards

Must-Have Tools:

- FLIR T540 thermal camera

- Kelman Transfix oil analyzer

- UE Ultraprobe ultrasonic detecto

3 Key Life-Extension Tips

- Load Management: Keep 65-80% loading

- Oil Reconditioning: Add adsorption degassers (2-3x oil life)

- Corrosion Protection: Apply polyurethane tank coating