1. Key Advantages of Oil-Immersed Transformers

- Superior Cooling Performance

Oil-immersed transformers use mineral oil for cooling, achieving 40%+ better heat dissipation than dry-types. 2024 tests show S13 models maintain 15-20℃ lower winding temperatures at full load. - Extended Service Life

Average lifespan reaches 25-30 years thanks to:

- Oil insulation slowing aging

- Sealed construction preventing oxidation

- Conservator tanks regulating pressure

- Cost Efficiency

| Type | Initial Cost | 10-Year TCO | Best For |

|————-|————-|————-|——————-|

| Oil S11 | ¥850/kVA | ¥1,200/kVA | Industrial plants |

| Dry SCB10 | ¥1,100/kVA | ¥1,500/kVA | Commercial buildings | - Maintenance Simplicity

Oil chromatography provides 3-6 month early warnings, while smart models now feature:

- Wireless oil/temperature monitoring

- Automatic fault alerts

- 5-year maintenance intervals

2. 4 Golden Selection Rules

- Capacity Calculation

Per GB/T 1094:

text

Required Capacity(kVA) = Max Load(kW) × 1.25(Safety Factor) / 0.9(Power Factor)

2024 Update: Solar/wind projects need +15% capacity buffer.

- Efficiency Choices

- S9 Series: Phasing out (banned by 2027)

- S11 Series: Best value (No-load loss ≤240W)

- S13 Series: Top performer (Saves ≥¥15,000/year)

- Environmental Adaptation

- High altitude: Derate 5% per 1000m

- Humid areas: IP55 protection

- Flammable zones: FR3 fire-resistant oil

- Supplier Evaluation

Must-have certifications:

□ ISO9001

□ State Grid qualified

□ Local service centers (≤24h response)

3. 4 Critical Maintenance Practices

- Oil Management

- Annual tests: Dielectric loss ≤0.05

- 5-year filtration: Particles ≤5μm

- Emergency: 50% water increase = Immediate shutdown

- Temperature Monitoring

- Normal: Top oil ≤85℃

- Warning: Hot spots ≥105℃

- New tech: Fiber-optic sensing (±1℃ accuracy)

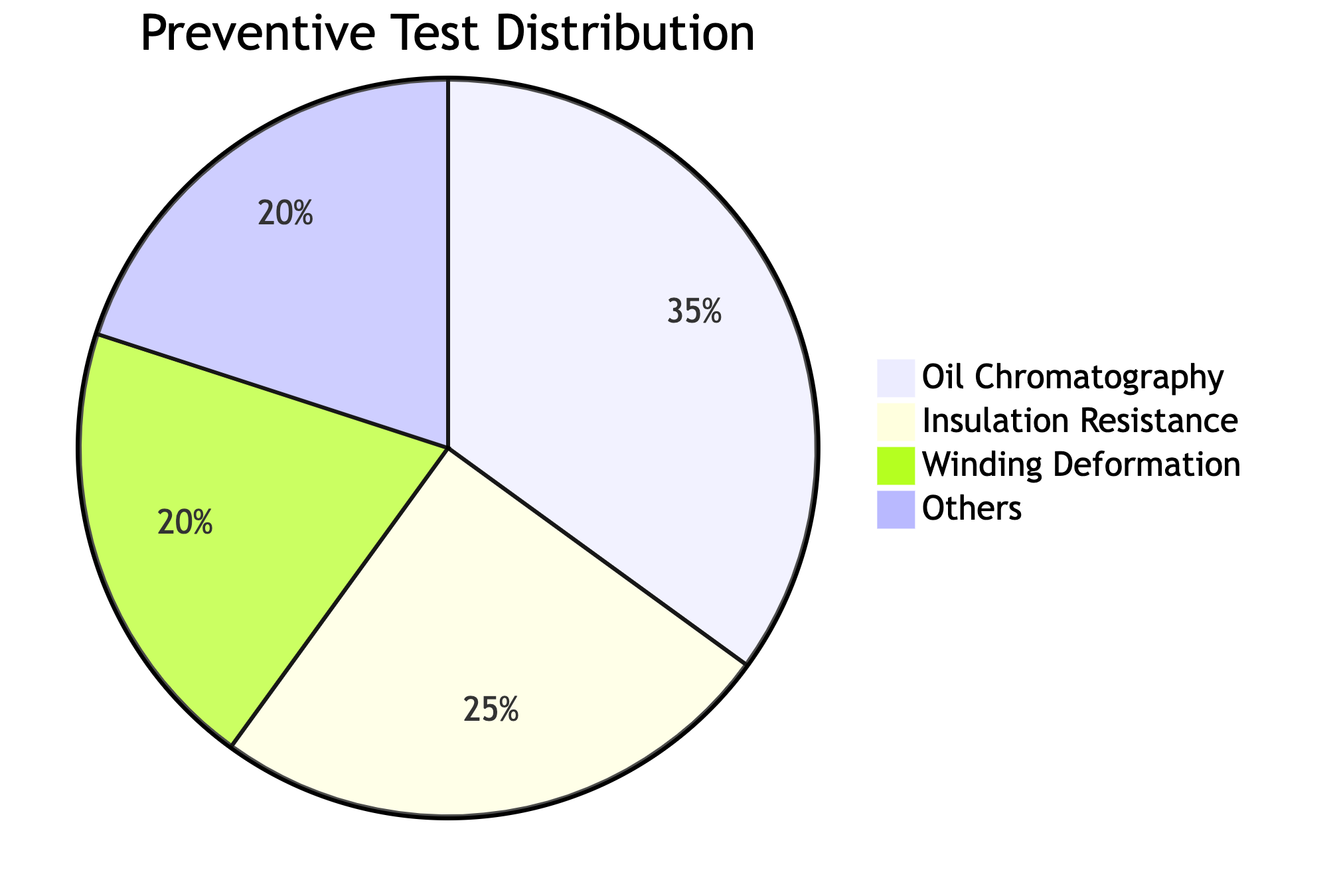

- Electrical Testing

- Emergency Response

Troubleshooting guide:

- Abnormal oil level: Check seals before refilling

- Sudden oil spray: Cut power immediately

- Gas alarm: Sample analysis required