This white paper systematically elaborates the technological system of intelligent oil-immersed transformers for new power systems, proposing a three-dimensional development path of “comprehensive condition perception – deep data mining – autonomous decision optimization”. Research shows that transformers adopting next-generation intelligent technologies can improve energy efficiency by 3-5 percentage points, extend service life by 8-10 years, and reduce maintenance costs by over 40%.

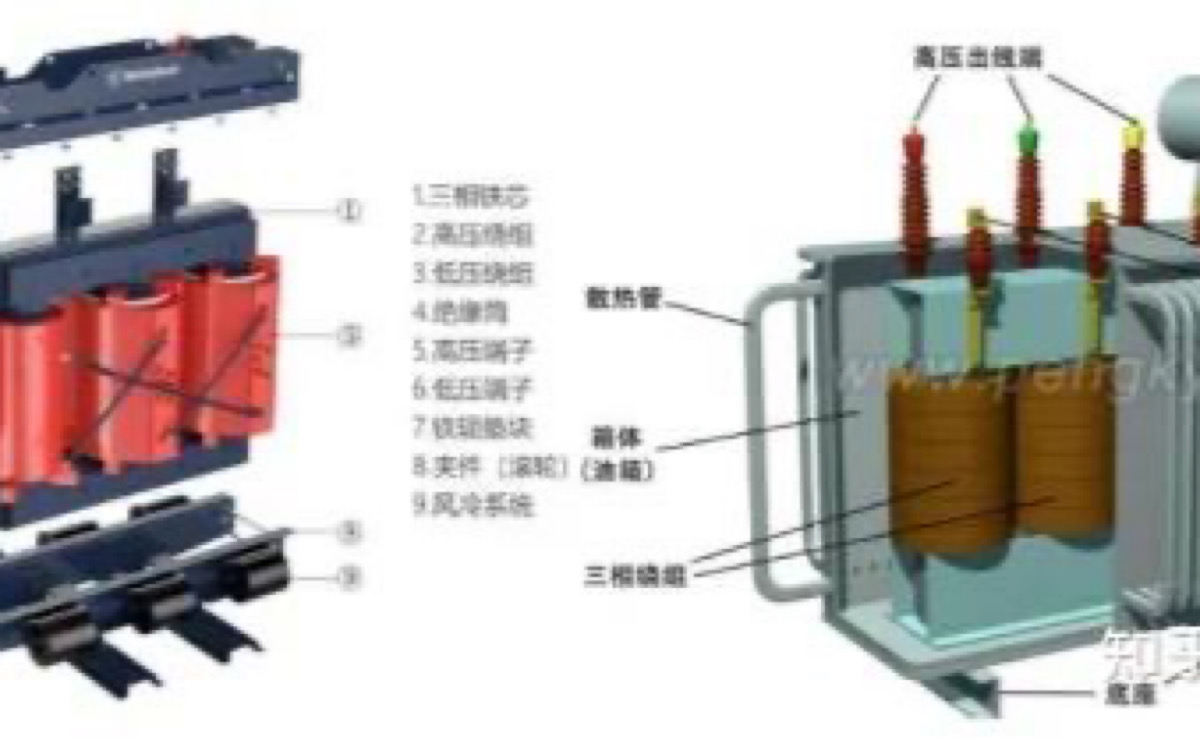

Chapter 1 Industry Status and Technical Challenges

1.1 Market Supply-Demand Analysis

• Global market size: Reached $21.8 billion in 2023, with a CAGR of 5.7% (2024-2030)

• Energy efficiency standard evolution: Upgrade roadmap from IE1 to IE4

• Pain point analysis: Three major challenges in environmental compliance, energy efficiency improvement, and intelligent transformation

1.2 Technological Bottleneck Breakthroughs

- Heat dissipation efficiency limit: Thermal resistance coefficient of existing oil duct design ≥0.25K/W

- Insulation material constraints: Traditional insulation paper thermal aging life <30 years

- Condition assessment blind spots: Existing monitoring parameter coverage <65%

Chapter 2 Core Technological Breakthroughs

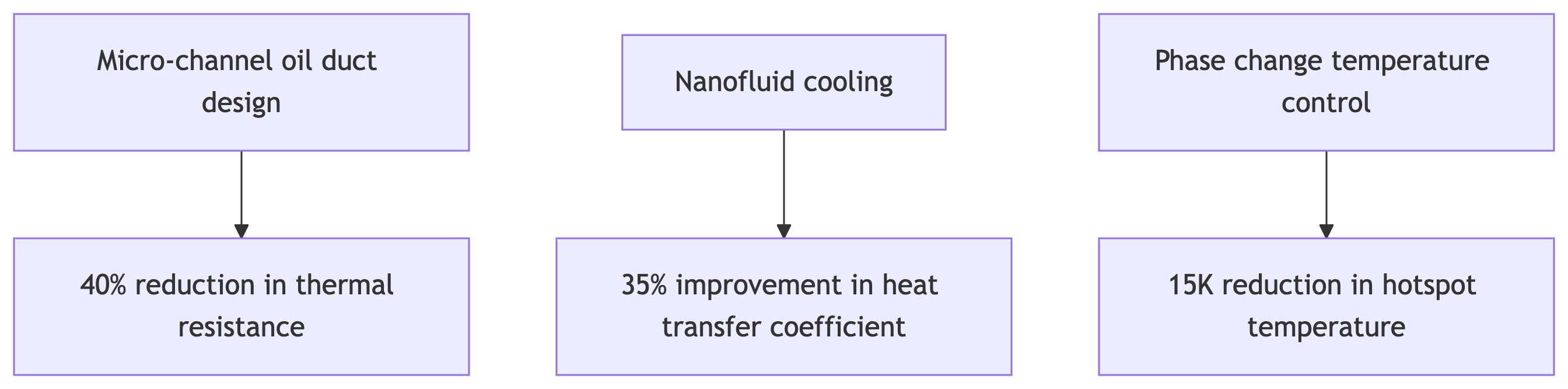

2.1 Innovative Cooling Technologies

2.2 New Insulation System

- Cellulose/polypropylene composite insulation paper: Temperature rating increased from 105°C to 130°C

- Boron-nitrogen modified insulating oil: Breakdown voltage ≥75kV/2.5mm

- Self-healing insulation coating: Micro-crack self-repair rate >90%

2.3 Intelligent Sensing System

“Five-dimensional sensing” technology matrix:

- Electromagnetic sensing (0.1Hz-1MHz wideband measurement)

- Thermal sensing (distributed optical fiber temperature measurement)

- Mechanical sensing (MEMS vibration monitoring)

- Chemical sensing (online chromatographic analysis)

- Environmental sensing (meteorological parameter fusion)

Chapter 3 Digital Twin Platform

3.1 Architecture Design

3.2 Core Functions

- Real-time simulation: Electromagnetic-thermal-mechanical coupling calculation with time step ≤1ms

- Predictive maintenance: LSTM-based RUL prediction error <5%

- Virtual commissioning: Reduces field commissioning time by 60%

Chapter 4 Typical Application Scenarios

4.1 Renewable Energy Plants

│── Photovoltaic plants: Adapt to ±10% voltage fluctuation

│── Wind farms: Short-circuit withstand capacity ≥25kA/2s

└── Energy storage systems: Cycle efficiency >99%

4.2 Urban Power Grids

• Intelligent voltage regulation: 0.5% voltage adjustment accuracy

• Load forecasting: 24-hour error <3%

• Fault isolation: Operation time <20ms

Chapter 5 Standards and Testing

5.1 New Testing System

tabular

Test Item | Traditional Method | Intelligent Testing Solution ------------------|-------------------|----------------------------- Temperature Rise | Point measurement | 3D thermal field reconstruction Short Circuit | Single test | Digital twin simulation Life Assessment | Accelerated aging | Multi-factor coupling model

5.2 Certification Standards

- IEC 60076-27:2024 Standard for Intelligent Transformers

- IEEE C57.156-2023 Guide for Digital Twin Applications

- GB/T 41009-2024 Specification for Eco-friendly Insulating Oil

Chapter 6 Development Recommendations

- Technology roadmap: Complete material system upgrade by 2025, achieve full-scenario intelligence by 2030

- Industrial ecosystem: Establish “material-equipment-system” collaborative innovation alliance

- Policy support: Improve carbon footprint accounting and green financial support