As the core equipment of power systems, distribution transformers directly impact grid efficiency and power supply reliability. This article systematically analyzes how to evaluate their performance through key parameters and provides professional selection recommendations from a technical perspective.

1. Core Performance Indicators of Distribution Transformers

1.1 Energy Efficiency Analysis

According to the latest national standard GB 20052-2020:

- Tier 1 Efficiency: 40-50% reduction in no-load loss (recommended models: SCB14/SH16)

- Tier 2 Efficiency: 20-30% loss reduction (representative model: SCB13)

- Tier 3 Efficiency: Basic standard (phasing out)

Field Data: An industrial park achieved annual savings of 128,000 kWh after replacing S11 with SCB14 transformers.

1.2 Load Characteristics

- Optimal Economic Operation Range: 40%-75% of rated capacity

- Overload Capacity: Oil-immersed transformers outperform dry-type in short-term overload performance

2. In-Depth Interpretation of Key Parameters

| Parameter | Premium Specification | Inferior Performance | Testing Method |

|---|---|---|---|

| No-load Current | <0.5% rated current | >1% rated current | Open-circuit test |

| Impedance Voltage | 4-6% | ±15% deviation | Short-circuit test |

| Temperature Rise | ≤65K (oil-immersed) | >75K | IR thermography |

| Partial Discharge | <10pC | >100pC | PD detector |

3. Selection Decision Matrix

3.1 Application Scenario Matching

- Commercial Complexes: Prioritize SCB14 dry-type (fire safety requirements)

- Industrial Parks: Recommend S13-M oil-immersed (cooling advantages)

- Renewable Power Plants: Require OLTC-equipped SZ series

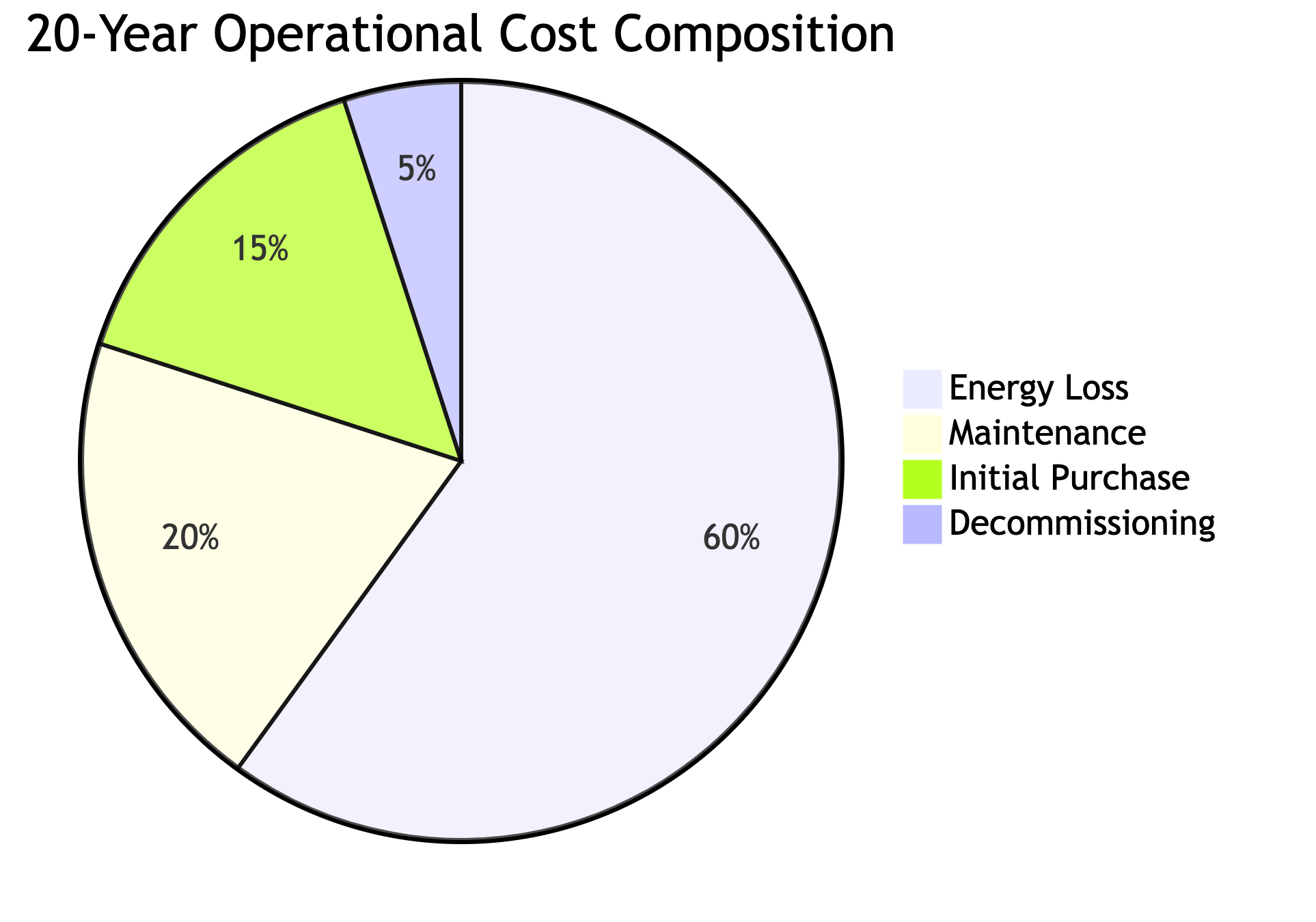

3.2 Lifecycle Cost Analysis

4. Industry Cutting-Edge Technologies

- Amorphous Core Transformers: 70-80% reduction in no-load loss

- Smart Monitoring Systems: Integrated temperature/vibration/dissolved gas analysis

- Vegetable Insulating Oil: Flash point exceeding 350℃

5. Common Selection Misconceptions

- “Bigger Capacity is Better”: Operation below 30% load reduces efficiency

- Focusing Only on Purchase Price: Neglecting long-term electricity cost differences (efficient models recover cost difference in 2-3 years)

- Ignoring Harmonic Effects: Modern loads require special attention to K-factor

6. Maintenance Recommendations

- Routine Inspection Focus:

- Oil level/temperature monitoring

- Abnormal noise detection

- Connection point IR scanning

- Preventive Test Cycles:

- Oil analysis: Annual

- Winding inspection: Triennial

Industry Case: A tertiary hospital achieved annual savings of ¥830,000 through high-efficiency distribution transformers + smart monitoring system, with a payback period of only 2.1 years.

When selecting distribution transformers, adopt the principle of “efficiency first, moderate advancement,” balancing initial investment and long-term operational costs. Prioritize next-generation products with smart monitoring interfaces to accommodate future smart grid upgrades.