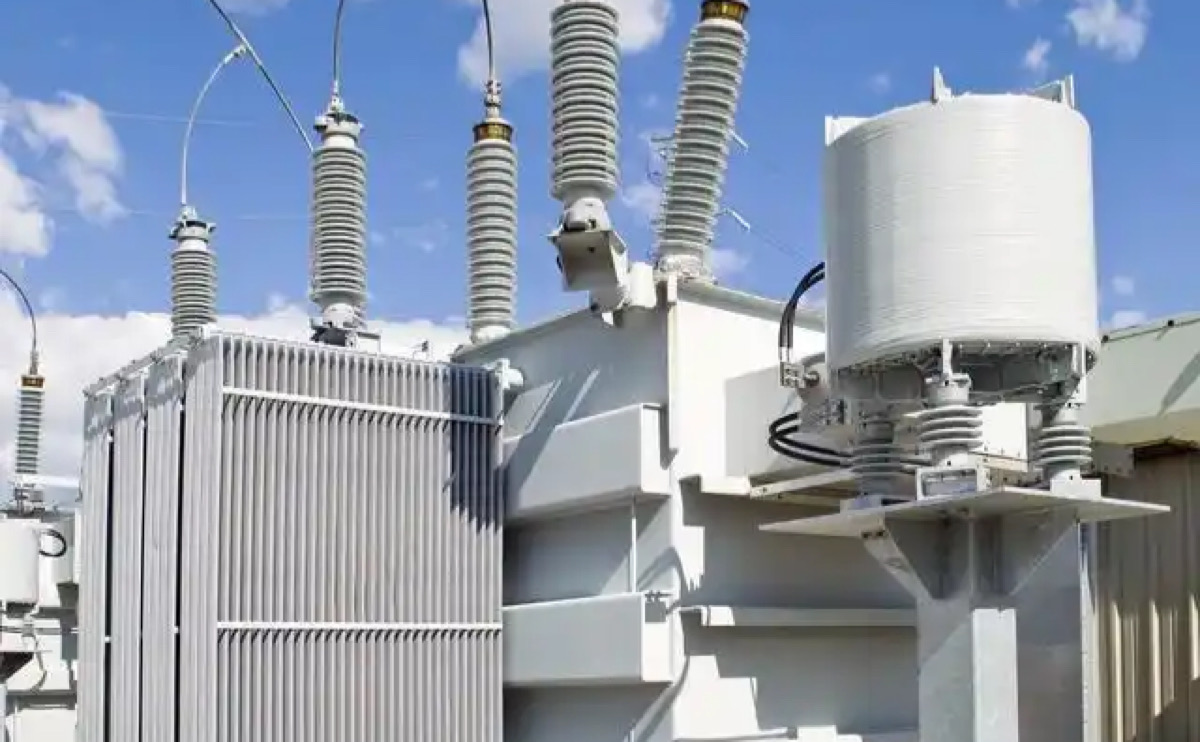

Oil-immersed transformers are essential electrical devices that use insulating oil for both cooling and insulation, widely employed in power distribution systems for their reliability, high efficiency, and cost-effectiveness. They excel in heat dissipation and overload capacity, making them ideal for medium to large-scale power applications.

1. Evolution of New-Generation Oil-Immersed Transformer Technology

1.1 Core Technological Innovations

- Superconducting Material Applications

- Utilizes second-generation high-temperature superconducting tapes

- Operating temperature increased to 77K (-196℃)

- Load loss reduction exceeding 90%

- Intelligent Oil Management System

- Nanoscale oil quality sensor arrays

- Real-time oil aging prediction algorithms

- Automatic oil replenishment and regeneration system

- Digital Twin Platform

- Real-time multi-physics field simulation

- 98% accuracy in lifespan prediction

- Virtual commissioning functionality

2. Full-Scenario Application Solutions

2.1 New Power System Adaptation Solutions

| Application Requirements | Technical Solution | Typical Model | Performance Indicators |

|---|---|---|---|

| High renewable energy penetration | Wide-frequency impedance optimization | S□-WPT | 2-1500Hz adaptive |

| Flexible HVDC transmission | DC bias suppression | S□-HVDC | Tolerates 10% DC component |

| Virtual power plants | Fast response design | S□-VPP | Millisecond-level regulation |

2.2 Special Series for Extreme Environments

- Arctic Models: S□-ARCTIC

- Cold start at -60℃

- Ice-wind load resistant design

- UV aging protection

- Desert Models: S□-DESERT

- Withstands 50℃ high temperature

- Sand-dust proof sealing

- Self-cleaning heat dissipation

3. Smart Maintenance 4.0 System

3.1 Holographic Sensing System

- Quantum Sensor Network

- Single-molecule detection in oil

- 3D magnetic field imaging

- Nanoscale vibration monitoring

- AI Maintenance Brain

- Knowledge graph driven

- Autonomous decision system

- Multi-objective optimization engine

3.2 Metaverse Maintenance Platform

- Digital twin interaction

- AR remote expert guidance

- Virtual training system

- Carbon-energy efficiency digital twin

4. Zero-Carbon Transformer Technology

4.1 Carbon Neutrality Solutions

- Full Lifecycle Carbon Management

- Blockchain carbon footprint tracing

- Carbon-neutral manufacturing process

- End-of-life recycling carbon offset

- Green Innovative Materials

- Plant-based insulating oil

- Biodegradable materials

- Low-carbon silicon steel

4.2 Energy Recovery Systems

- Waste heat power generation

- Vibration energy harvesting

- Electromagnetic field energy utilization

- 15% comprehensive efficiency improvement

5. Global Benchmark Cases

5.1 Southeast Asian Island Microgrid Project

- Model: S□-ISLAND-10/35

- Technological breakthroughs:

✓ C6 salt spray resistance

✓ Typhoon-level seismic resistance

✓ Off-grid autonomous operation

5.2 Eurasia Land Bridge Converter Station

- Model: S□-EAB-400/500

- Innovation records:

✓ Multi-national standard compatibility

✓ Intelligent harmonic management

✓ 99.9999% availability rate

This white paper is technically guided by the CIGRE Transformer Working Group. For detailed technical parameters or customized solutions, please contact regional technical service centers. The new-generation oil-immersed transformers can achieve 40% efficiency improvement, 50% carbon emission reduction, and 60% maintenance cost reduction, providing critical technological support for global energy transition.