I. The Inevitable Trend of Intelligent Transformation for Distribution Transformers

(1) Pain Points in Traditional Maintenance

- Low manual inspection efficiency: Data from a power supply company shows traditional manual inspections average 4.5 hours per unit, with only 68% fault detection accuracy.

- Delayed fault warnings: Statistics indicate that about 73% of transformer failures exhibit detectable anomalies before occurring.

(2) Core Features of Smart Distribution Transformers

- Multi-dimensional condition monitoring: Integrates 12 types of sensors (temperature, vibration, partial discharge, dissolved gas analysis, etc.).

- Edge computing capability: Equipped with AI chips for localized fault diagnosis.

- Digital twin interface: Supports bidirectional data exchange with grid dispatch systems.

II. Analysis of Key Technologies for Smart Distribution Transformers

1. Comparison of Condition Monitoring Technologies

| Monitoring Aspect | Traditional Method | Smart Solution | Accuracy Improvement |

|---|---|---|---|

| Temperature | Infrared spot checks | Fiber-optic sensing | ±0.5℃ → ±0.1℃ |

| Dissolved Gas | Offline lab tests | Online chromatography | 7-day cycle → Real-time |

| Mechanical Vibration | Manual auscultation | Accelerometer-based | Qualitative → Quantitative |

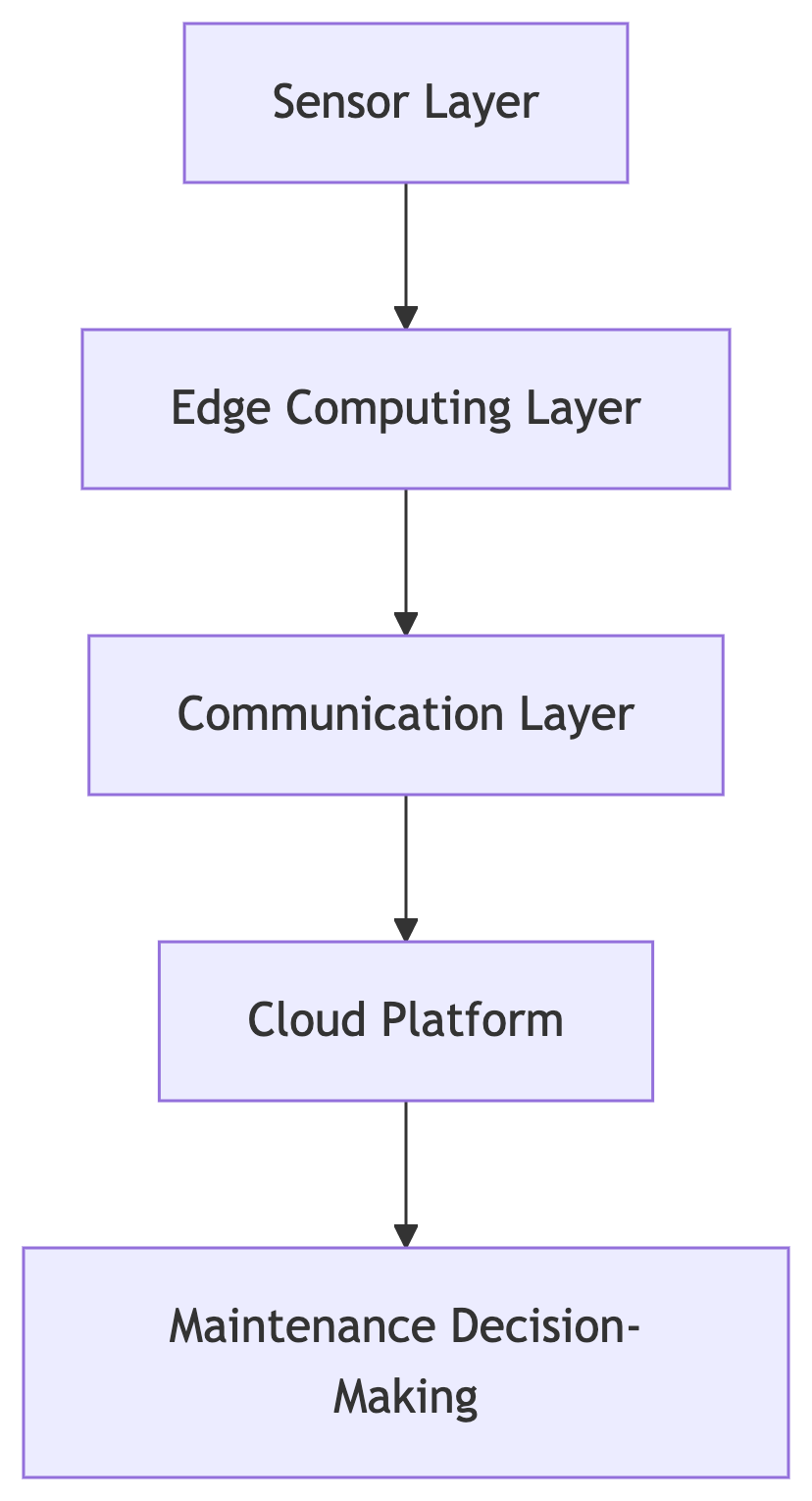

2. Typical Architecture of Smart Distribution Transformers

III. Economic Benefit Model of Intelligent Upgrades

(1) Cost Structure Analysis

- Hardware retrofitting: ~$4,200–$11,200/unit (including sensors and communication modules).

- Software system: $70,000–$280,000 (scale-dependent).

- Training costs: ~$700 per person.

(2) Case Study: ROI Calculation

After retrofitting 32 distribution transformers in an industrial park:

- 62% reduction in manual inspection costs.

- 78% shorter outage durations.

- Annual energy savings: $49,000.

- Payback period: 2.3 years.

IV. Implementation Roadmap Recommendations

- Phased Approach:

- Phase 1: Install basic monitoring (temperature, load).

- Phase 2: Deploy edge computing units.

- Phase 3: Build digital twin systems.

- Vendor Selection Criteria:

- Hardware compatibility: Must support IEC 61850 standards.

- Data openness: Provide standardized APIs.

- Cybersecurity: Comply with China’s Class 3 Cybersecurity Standards.

V. Industry Outlook

(1) Adaptability to New Power Systems

- Renewable integration: Smart transformers autonomously regulate voltage fluctuations (±5% → ±2%).

- Demand response: 40% increase in virtual power plant participation capacity.

(2) Future Technology Trends

- Self-healing: Expected by 2026 (e.g., partial discharge self-repair).

- Blockchain: Full lifecycle data immutability.

Practical data shows intelligent upgrades improve overall maintenance efficiency by 3–5x. Power utilities should establish a closed-loop “monitor-diagnose-decide-optimize” management system, prioritizing transformers over 5 years old with >60% load rates.