With the development of the power industry, dry-type transformers have been widely adopted in various electrical applications due to their unique advantages. This oil-free transformer design not only enhances safety but also reduces maintenance costs, making it particularly suitable for locations with stringent fire prevention requirements. This article provides a comprehensive analysis of the technical features, application scenarios, and selection criteria for dry-type transformers.

Technical Advantages of Dry-Type Transformers

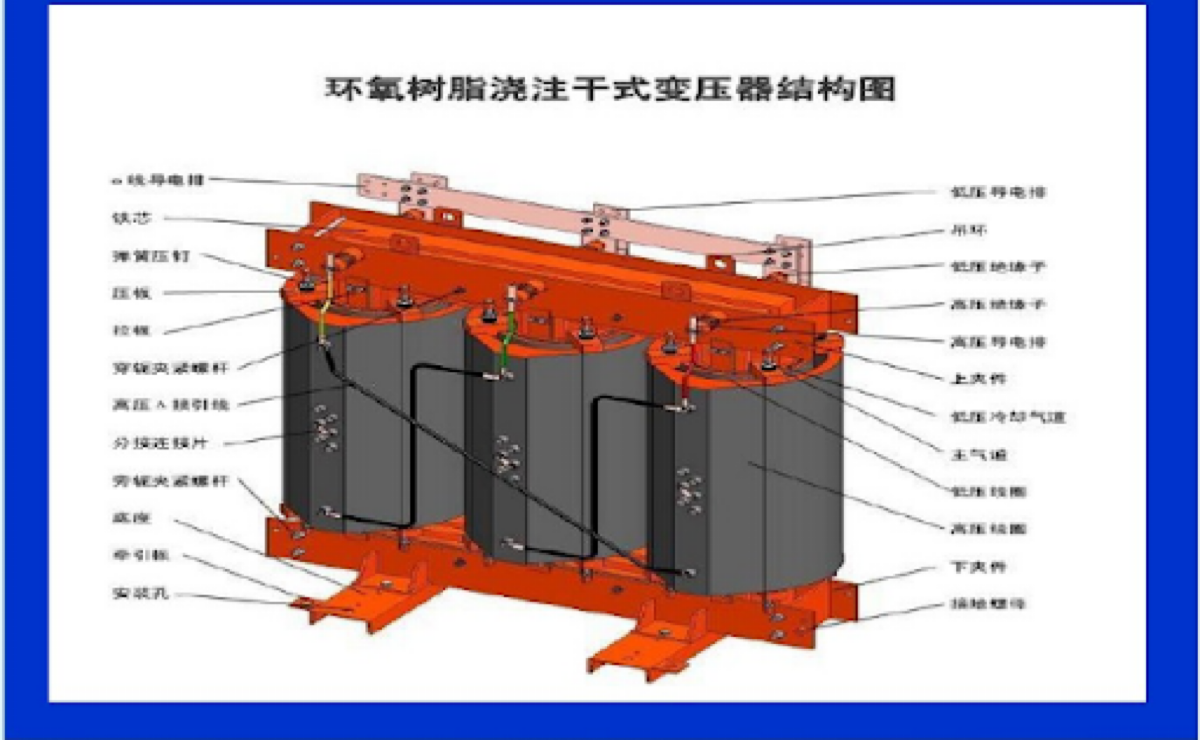

- Superior Fire Resistance: Utilizing epoxy resin casting or vacuum pressure impregnation processes, it completely eliminates fire risks associated with oil-immersed transformers.

- Eco-Friendly and Energy-Efficient Design: Complies with RoHS environmental standards, features low operational losses, and maintains noise levels below 65 decibels.

- Compact Structure: 30% smaller in size compared to oil-immersed transformers of the same capacity, saving installation space.

- Smart Monitoring Interface: New-generation models come equipped with online temperature monitoring and fault early-warning systems.

Typical Application Scenarios

- Commercial Complexes: Shopping malls and office buildings prioritize dry-type transformers to ensure electrical safety in high-density areas.

- Industrial Manufacturing: The optimal choice for explosion-proof environments like chemical plants and pharmaceutical factories.

- Public Facilities: Standard equipment for critical public spaces such as hospitals, schools, and airports.

- Renewable Energy Sector: Essential supporting equipment for photovoltaic power stations and wind farms.

Professional Selection Advice

- Energy Efficiency Rating: Opt for Class 1 energy-efficient dry-type transformers for better long-term economics despite higher initial investment.

- Insulation Class Consideration: Class F or H insulation systems ensure stable operation in high-temperature environments.

- Protection Rating Matching: Outdoor installations require IP54 or higher protection ratings.

- After-Sales Service: Choose reputable brands offering 10+ years of warranty coverage.

Maintenance Guidelines

Regular inspections of winding temperature, insulation resistance, and cooling systems are crucial for ensuring long-term reliability. Professional quarterly inspections are recommended, with special attention to checking for cracks or discharge marks on epoxy resin surfaces. Maintain proper ventilation in transformer rooms with ambient temperatures below 40°C.

Market Development Trends

With the acceleration of smart grid construction, dry-type transformers are evolving toward intelligent solutions. New-generation products incorporate IoT technology for remote monitoring and energy management. Meanwhile, transformers using advanced nano-composite insulation materials will further improve energy efficiency and service life.

When selecting dry-type transformers, consulting professional power engineers is advised to choose the most suitable models and specifications based on actual electrical loads and site conditions. Users interested in dry-type transformer prices or brand performance comparisons may refer to authoritative industry evaluation reports.